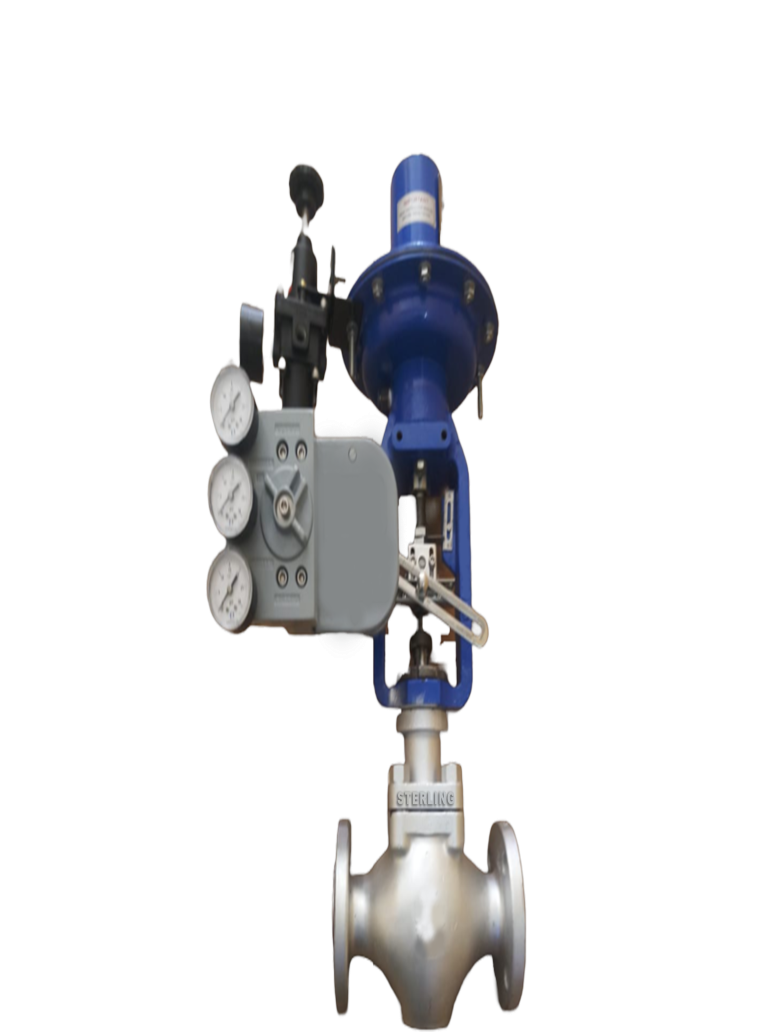

The Golbe Control Valve threaded seat globe control valve is designed for general service applications up to the limits of the ANSI 800 pressure class rating. These general service applications include process events such as erosion, abrasion, corrosion, cavitation, and flashing found in most process control industries.

The Golbe Control Valve has several standard options such as temperature extensions, metal bellows seals, heating jackets, high-performance metal sealing trim, soft sealing trim, ceramic trim, noise attenuation, cavitation prevention trim sets, etc. In addition to these options, the valves can be specialized to meet the exact process needs such as the NACE version for sour gas service, cleaned for specific services (e.g. Oxygen, Chlorine, High Purity, etc.).

• DN 6 to DN 250 (1/2″ to 12″)..

• PN 20, PN 40,Class 150 to Class 2500.

We have a proven track record of providing professional product services that enable businesses to reach new customers

All Rights Reserved © 2022 Sterling Valve and Controls | Designed by Riyadvi Software Technologies Pvt Ltd