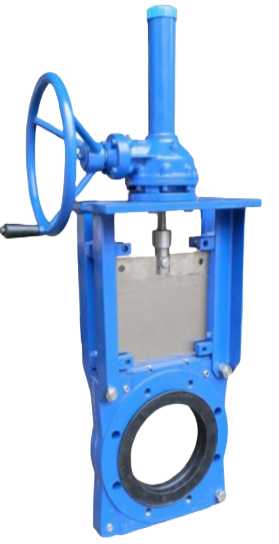

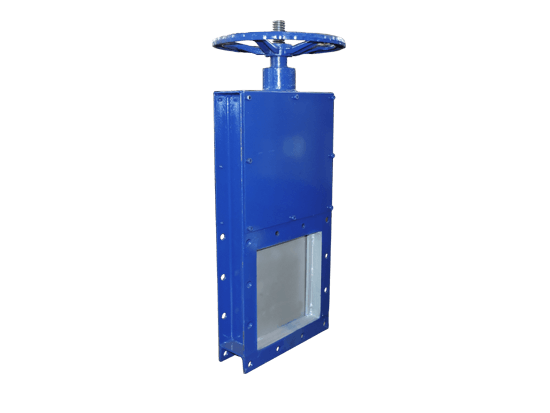

Knife gate valves get their name from their ability to cut through solid-containing mediums. They operate by elevating a circular or rectangular gate out of the media’s path. Knife gate valves are commonly utilized when a straight-line fluid flow with minimal restriction is required.

The sealing surfaces between the gate and seats are flat. Knife gate valves were created with the pulp and paper industry in mind. Stringy pulp impinged between the wedge and seat of a standard gate valve, blocking flow shut-off. The material is chopped up as it passes through the valve, which is how they work.

• Bare-shaft, hand wheel , chain wheel & Gearbox.

We have a proven track record of providing professional product services that enable businesses to reach new customers

All Rights Reserved © 2022 Sterling Valve and Controls | Designed by Riyadvi Software Technologies Pvt Ltd