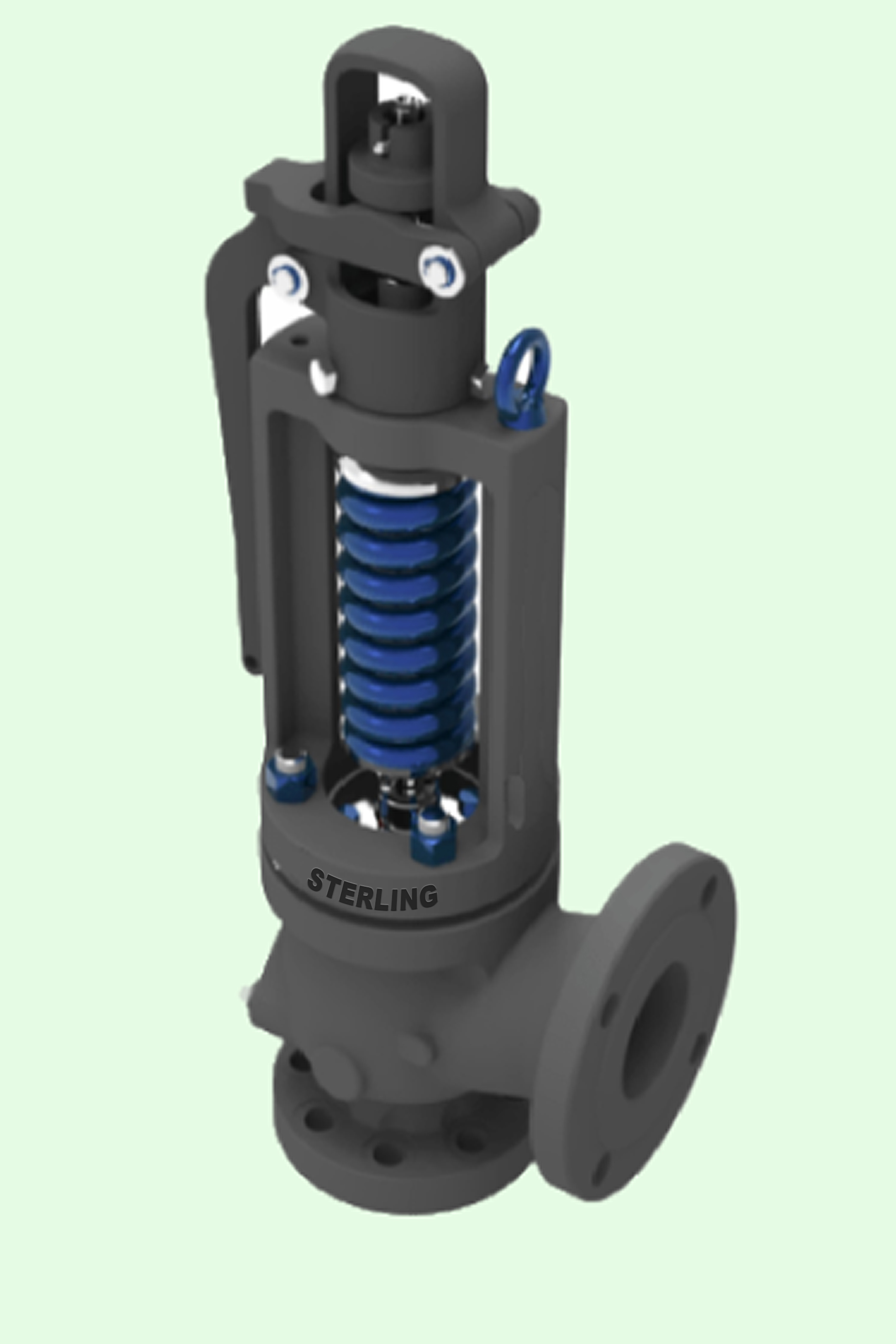

The primary function of a safety valve is to protect property and life. Because a safety valve is often the last device to prevent catastrophic failure under pressure conditions, the valve must work at all times i.e. it must be 100% reliable. Safety valves should be installed wherever the maximum allowable working pressure of a system is.

The pressure-containing vessel is likely to be exceeded, in particular under fault conditions due to the failure of another piece of equipment in the system. The term “Safety Valve” and “Relief Valve” are generic terms to describe a variety of pressure relief devices. A wide range is available based on the application and required performance criteria.

• DN 50(2”) to DN 1000 (25”)

• Set Pressure Range- 15 psig to 6250 psig.

• API 600, API 603, ASME B 16.34

Testing Standard

• Electric, Pneumatic, and Hydraulic Actuators.

We have a proven track record of providing professional product services that enable businesses to reach new customers

All Rights Reserved © 2022 Sterling Valve and Controls | Designed by Riyadvi Software Technologies Pvt Ltd