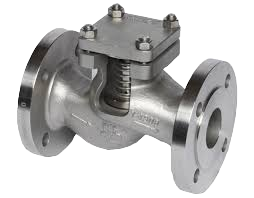

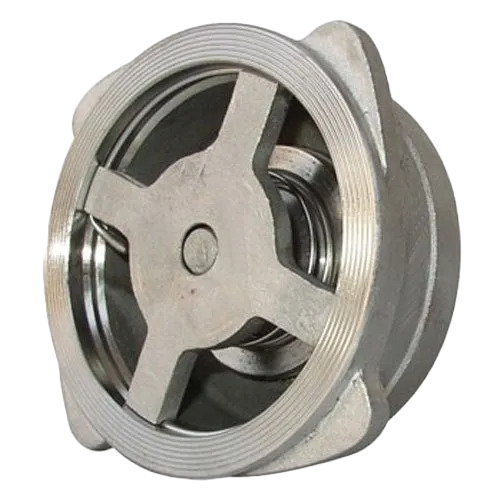

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid to flow through it in only one direction. Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave.

Check valves are generally installed in pipelines to prevent backflow. A check valve is a one-way valve, in which the flow can run freely one way, but if the flow turns the valve will close to protect the piping, other valves, pumps, etc. If the flow turns and no check valve is installed, a water hammer can occur.

We have a proven track record of providing professional product services that enable businesses to reach new customers

All Rights Reserved © 2022 Sterling Valve and Controls | Designed by Riyadvi Software Technologies Pvt Ltd