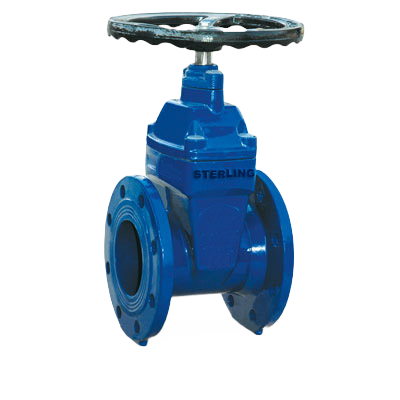

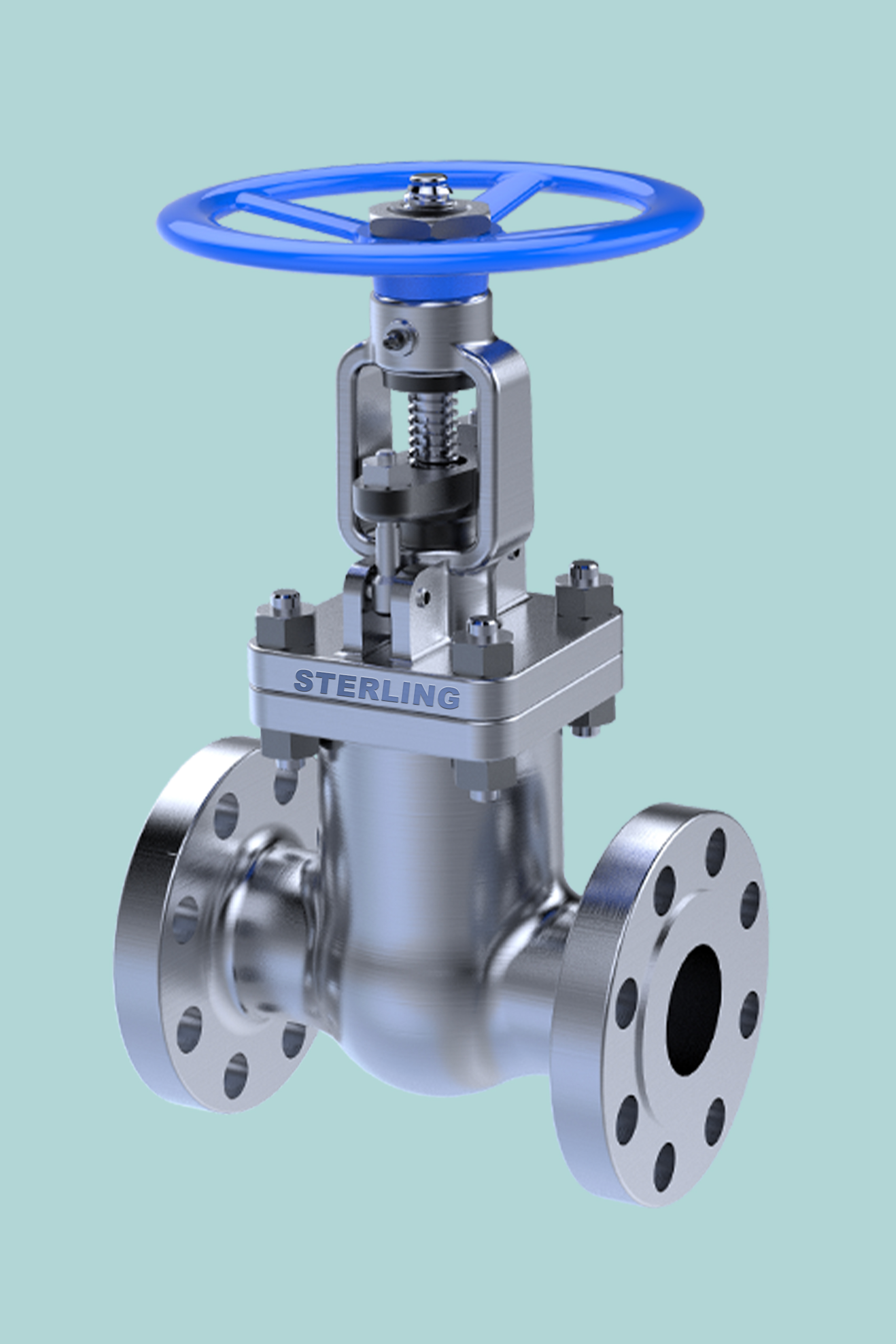

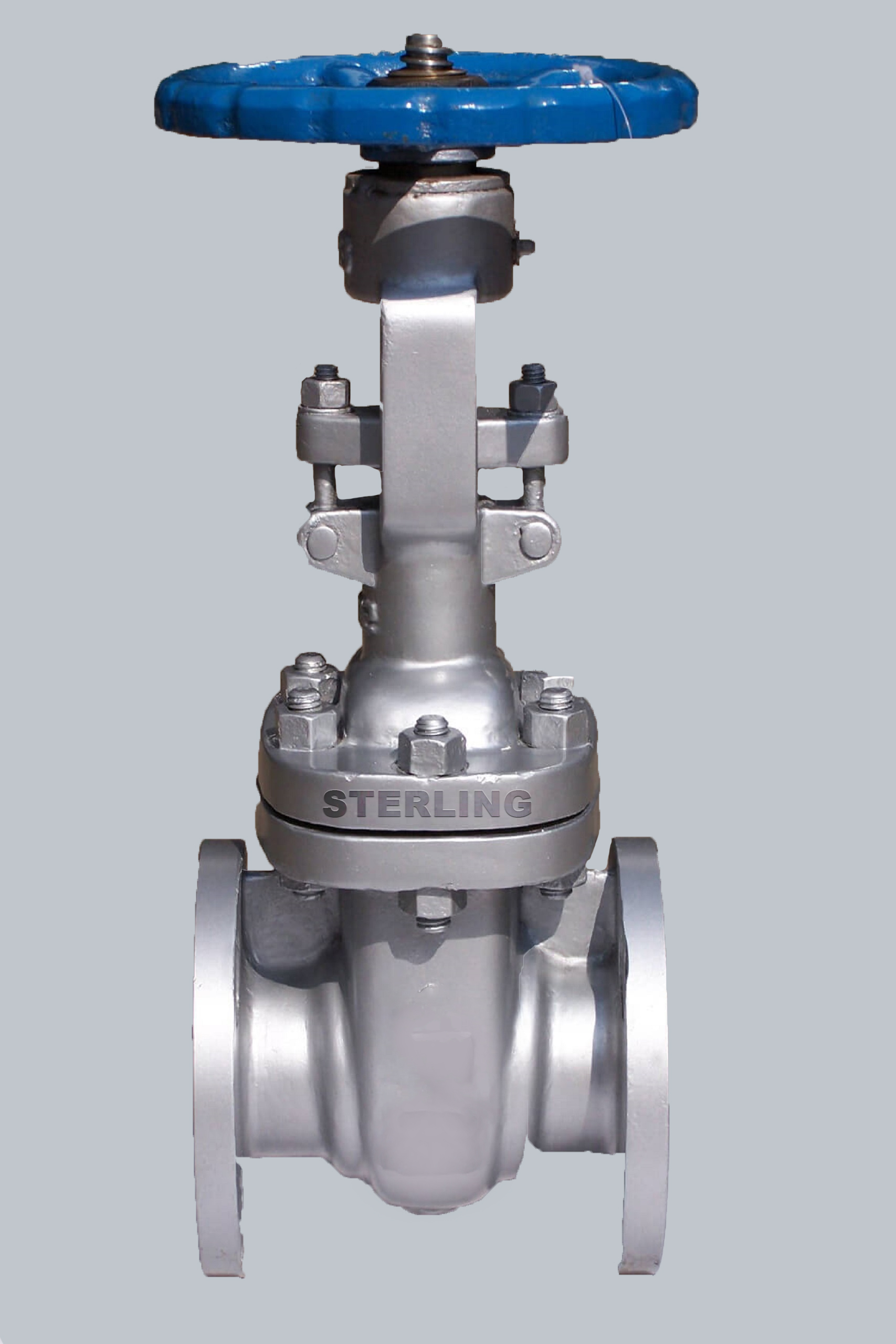

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully opened.

A gate valve is generally used to completely shut off fluid flow or, in the fully open position, provide full flow in a pipeline. Thus it is used either in the fully closed or fully open positions.

• API 600, API 603, ASME B 16.34

• Electric, Pneumatic, and Hydraulic Actuators.

We have a proven track record of providing professional product services that enable businesses to reach new customers

All Rights Reserved © 2022 Sterling Valve and Controls | Designed by Riyadvi Software Technologies Pvt Ltd