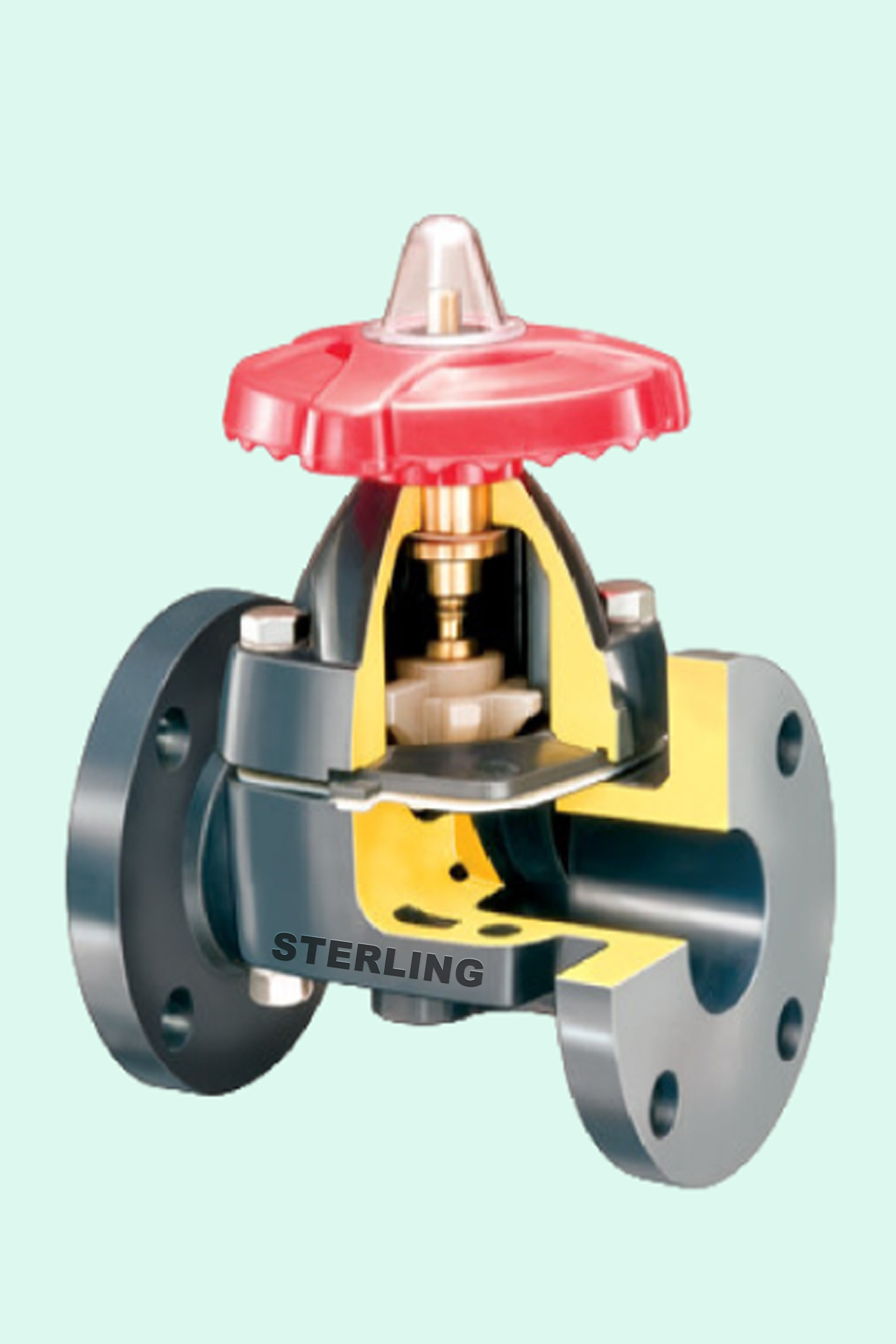

Diaphragm valves are used on shut-off and throttling service for liquids, slurries and vacuum/gas, and it is a quick opening valve. The seal is achieved by a flexible membrane, usually elastomer, and possibly reinforced with a metal part.

The membrane is tensed by the effect of a stem/compressor with lineal movement until contact is made against the seal of the body. The operating parts of the diaphragm valve are isolated from the flow. This makes this valve suitable for viscous flows and also hazardous, abrasive, and corrosive flows as its sealing system avoids any contamination towards or from the environment.

Diaphragm valves use a flexible sheet pressed close to the edge of a solid dam to narrow the flow path for fluid.

We have a proven track record of providing professional product services that enable businesses to reach new customers

All Rights Reserved © 2022 Sterling Valve and Controls | Designed by Riyadvi Software Technologies Pvt Ltd